BONDING AGENTS

Monobond®

Monobond® is a polymer latex additive for modifying cement concrete / mortar / plaster / grouts.

The addition of Monobond® improves mechanical properties especially flexure and tension. Due to low permeability of polymer modified systems, remarkable improvement in prevention of carbonation, chloride ion penetration is observed. Also chemical resistance improves significantly.

The addition of Monobond® imparts resilience to the cement matrix. Thereby improving impact resistance. Also the modified cement matrix cures in air, eliminating the necessity of wet curing.

It is necessary to mix Monobond® in water first prior to addition in cement mortar I concrete.

Application Procedure

- Mix Monobond® in water first prior to addition in cement mortar / concrete. Dosage 10% to 15% by weight of cement.

EL-MONOBOND®

Two Component Non Re-emulsifiable Epoxy Latex System

EL-MONOBOND® is a two component non re-emulsifiable epoxy latex system which can be used for plain and cement modified coating applications over concrete / plasted substrates.

Application Procedure

- EL-MONOBOND® system is brush applied and the substrate before application shall be free from loose particles, grease, etc. Thorough cleaning with water after abrading with wire brush

prior to application is to be carried out

- Stir vigorously for 5 minutes individual components of Part A & Part B, and mix the two parts in prescribed proportion thoroughly and add cement and clean water (as prescribed) slowly so as to form homogenous mix. Stir vigorously for 5 minutes and apply. Apply minimum 2 coats for waterproofing applications

- For bonding applications mix part A and part B in equal proportion by volume stir thoroughly to get a uniform mix and apply on the surface to be bonded after wetting the surface sprinkling with little water. Apply the mortar / concrete within half an hour

EPIBOND-11

Multifunctional Versatile Epoxy System

EPIBOND-11 is a multifunctional versatile epoxy system which can be used effectively for below application:

Application Procedure

As a bonding agent:

- To obtain good adhesion it is necessary to have a clean and sound substrate, which can be obtained by grinding, wire brushing, chipping, sandblasting, etc

- Mix Epibond-11 thoroughly in the prescribed proportion and apply on the clean, sound and dry substrate

- Apply concrete / cement plaster / gunite on the tacky Epibond-11 layer, which would be achieved approximately after 30 minutes of application and under any circumstances within one hour

- Best results are obtained when w/c ratio of the new concrete is as low as practicable

As an epoxy mortar:

- Mix Part A Epibond-11 and Part B Epibond-11 in the ratio of 1:1 by weight in a clean plastic container

- Stir thoroughly for 5-10 minutes so as to achieve a uniform mix

- Add component C - Graded Quartz filler slowly and mix thoroughly to achieve a uniform mortar mix

- The mortar (A+B+C) after mixing shall be used within 30 minutes hence it is ideal to use small mixes at a time

- Before application of mortar the surface to be primed with bond coat of Epibond-11 neat coating

- It is important to clean, degrease and abrade the substrate thoroughly before applying the bond coat using mechanical wire brushes

As an anti-corrosive coating:

- Mix Epibond-11 Base & Curing agent in prescribed proportion by weight and allow it to

remain for 10 minutes before application. Apply 2-3 coats of Epibond-11 with a time interval of 24 hours between coats

Internal coating to water tank:

- The adhesion of Epibond-11 is greatly impaired if the surface is not prepared thoroughly. Remove dirt, oily residues and existing coat if any by scrubbing with coarse wire brushes or chipping off the top layers

- Prior to Epibond-11 application, seal all the cracks, joints, etc. with EPCO® 1010 sealant. Mix Epibond-11 Base and Curing Agent in equal proportions by weight for 5 minutes. Keep it as it is in the container for 10 minutes before applying

- Apply minimum two coats of Epibond-11 on the surface keeping minimum 2 hours time interval between them

For injection grouting:

- The cracks and openings at junctions shall be cleaned for placing injection nipples. Thereafter the injection points placed approx. between 150mm to 300mm and shall be drilled to the depth of 75mm to 125mm. All the dust and loose particles shall be cleaned from the drilled points

- Injection nipples be placed and grouted with non-shrinking epoxy sealant/grout (HV grade). Even the cracks or openings between the injection points shall be sealed with sealant

- Using specialized injection instrument (ROHiBB INJECTOR) low viscosity grout Epibond-11 shall be injected through nipples. The process shall continue till the firm resistance from the surface is received. The pressure of injection may vary from 4kg/cm2 to 7kg/cm2

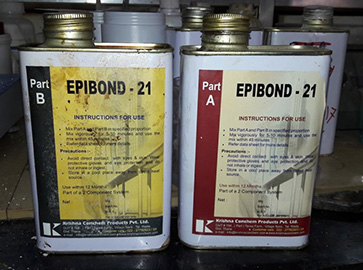

EPIBOND-21

Bonding New To Old Concrete

EPIBOND-21 is used to bond fresh concrete to concrete that is fully cured.

EPIBOND-21 will give monolithic bond capable of transmitting high stresses. In addition, EPIBOND-21 possesses excellent water and alkali resistance.

Application Procedure

- To obtain good adhesion it is necessary to have a clean and sound substrate, which can be obtained by grinding, wire brushing, chipping, sandblasting, etc.

- Mix EPIBOND-21 thoroughly in the prescribed proportion and apply on the clean and sound substrate

- Apply concrete / cement plaster / gunite on the tacky EPIBOND-21 layer which would be achieved approximately after 30 minutes of application and under any circumstances within one hour

- Best results are obtained when w/c ratio of the new concrete is as low as practicable

EPIBOND-21-LP

Bonding Agent with long pot life

EPIBOND-21-LP is used to bond fresh concrete to concrete that is fully cured. EPIBOND-21-LP will give monolithic bond capable of transmitting high stresses. In addition, EPIBOND-21-LP possesses excellent water and alkali resistance and has long tackfree time of 120 minutes. This would help in laying concrete/mortar even after 120 minutes of application of bond layer.

Application Procedure

- To obtain good adhesion it is necessary to have a clean and sound substrate, which can be obtained by grinding, wire brushing, chipping, sandblasting, etc.

- Mix EPIBOND-21-LP thoroughly in the prescribed proportion and apply on the clean and sound substrate

- Apply concrete / cement plaster / gunite on the tacky EPIBOND-21-LP layer which would be achieved approximately after 30 minutes of application and within two hours

- Best results are obtained when w/c ratio of the new concrete is as low as practicable

Plast-O-Grip

Bonding Agent for Plaster

Plast-O-Grip is an easy to use bonding agent for bonding plaster and old or new concrete. It is also effective in bonding plaster with brick masonry, mortar blocks

Plast-O-Grip will give monolithic bond when traditional bonding agents such as cement slurry cannot always be relied upon to provide good adhesion.

Application Procedure

- To obtain good adhesion it is necessary to have a clean and sound substrate, which can be obtained by grinding, wire brushing, chipping, sandblasting, etc

- Moisten the surface with water

- Apply a Coat of Plast-O-Grip over moist surface by spraying

- When a coat is tacky, Apply cement plaster as per standard plastering practices

- Tacky period may change as per atmospheric condition, quality of parent concrete, bricks or mortar blocks

GRIPSUM Plus

Bonding Agent with Gypsum & plaster

It is used as concrete bonding agent with gypsum & plaster. It dries to form a tacky coating, unaffected by alkalinity of cement and gypsum. On application, Gripsum Plus strengthens the bonding strength substantially and is not influenced by moisture allowing for use of GRIPSUM Plus on both interior and exterior applications.

Application Procedure

- Remove all the loose or disintegrated concrete, dust, oil, or any other foreign material

- On a clean surface, apply a coat of GRIPSUM Plus, either with brush / roller or spray

- Allow to dry until tacky to touch (may take 10-20 minutes, depending upon the relative humidity)

- If the sufficient tackiness is not developed, one may apply a second coat of GRIPSUM Plus

MONOBOND®-SBR

Styrene Butadiene Polymer Latex Additive For Polymer Modified Concrete / Mortar / Grouts.

MONOBOND®-SBR is a modified milky white styrene butadiene polymer latex liquid additive used for bonding, waterproofing, repair mortar and concrete. The addition of MONOBOND®-SBR enhances mechanical properties especially flexure, impact, tensile strength, shrinkage & permeability reduction and prevents cracking. It improves resistance against ingress of chloride ions, alkalies, sulphates significantly.

Application Procedure

- Surface Preparation: Remove all loose particles, dust and dirt from existing concrete substrate using wire brush or scrubber. De-grease the surface by using compatible solvents. Cut the section in any geometrical shape for at least 10 mm depth or as required at extreme edges to avoid feathering & to provide strong bond. Roughen the surface with wire brush, light scrabbling or grit blasting for better mechanical anchorage. Expose corroded bars in repair areas & clean all loose corrosion scales. Apply Rust converting primer-Feovert followed by anti-corrosive epoxy coating system-IPNet RB 2 coats

For Bond Coat:

- In a clean container, add MONOBOND®-SBR and Cement in equal proportion by weight. Mix it thoroughly to form a desired consistency. Apply the mix by brush on the surface of uniform thickness. Pour mortar or concrete over it within the tacky period of MONOBOND®-SBR bond coat

For Mortar / Concrete:

- In a clean container, add Monobond SBR, Cement, and Sand in proportion 1:5:15 by weight. Mix it using suitable sized drum with heavy-duly electrical drill machine filled with spiral paddle mixer at slow speed of 400-500 rpm. Add water slowly until required consistency is achieved. Do not add excess water. In the same proportion mix add 10 mm aggregates upto 20% for preparing concrete. Place this mortar and concrete over the prepared surface

For Waterproofing:

- In a clean container, add Monobond SBR and Cement in 1:2 proportion by weight. Mix it thoroughly to form a thick consistency uniform mix. Apply the mix by brush on the water saturated surface of uniform thickness. Use this mix within pot life

Goldbond®-321

Old to Old Segmental Bonding in Concrete

Goldbond®-321 is a two component thixotropic solvent free, non-shrinking adhesive confirming to FIP 9/2 standards.

Application Procedure

- Goldbond®-321 can be applied by trowel spatula with a gloved hand. Segments shall be post tensioned within the open time of the adhesive